Authors:

(1) Jorge Francisco Garcia-Samartın, Centro de Automatica y Robotica (UPM-CSIC), Universidad Politecnica de Madrid — Consejo Superior de Investigaciones Cientıficas, Jose Gutierrez Abascal 2, 28006 Madrid, Spain ([email protected]);

(2) Adrian Rieker, Centro de Automatica y Robotica (UPM-CSIC), Universidad Politecnica de Madrid — Consejo Superior de Investigaciones Cientıficas, Jose Gutierrez Abascal 2, 28006 Madrid, Spain;

(3) Antonio Barrientos, Centro de Automatica y Robotica (UPM-CSIC), Universidad Politecnica de Madrid — Consejo Superior de Investigaciones Cientıficas, Jose Gutierrez Abascal 2, 28006 Madrid, Spain.

Table of Links

2 Related Works

3 PAUL: Design and Manufacturing

4 Data Acquisition and Open-Loop Control

4.3 Dataset Generation: Table-Based Models

5 Results

5.3 Performance of the Table-Based Models

5.5 Weight Carrying Experiments

A. Conducted Experiments and References

5.4 Bending Experiments

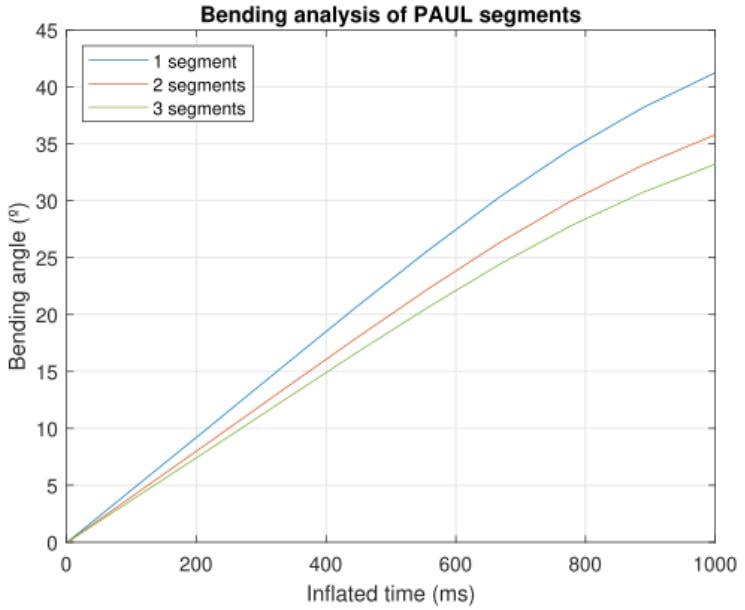

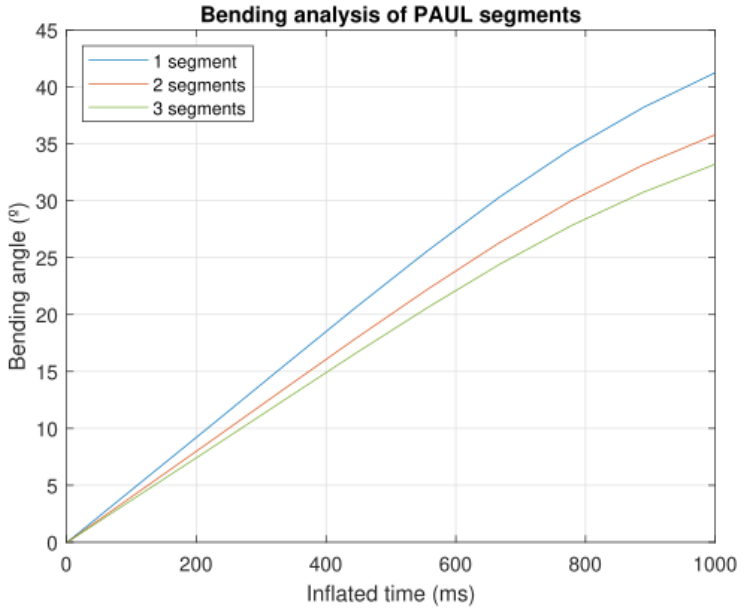

The first experiment consisted of analysing the deflection of a segment versus swelling time. For this purpose, one of the bladders was inflated continuously, in intervals of 100 ms. For each time, PAUL end coord

where x0 and y0 denote initial position of PAUL end.

Since the weight of the subsequent modules influences the behaviour of the first segment, the experiment was repeated by placing first one and then two additional segments. The results are shown in Figure 18.

As can be seen, PAUL is capable of bending up to 40◦ to its vertical axis and the addition of new segments does not cause any noticeable decrease in its bending capacity.

Although it remains far from the 80◦ of [28] or the 70◦ of [32], Pneunet segments and therefore more flexible, this is an acceptable bending capacity. Moreover, the fact that it does not substantially lose its bending capacity by adding segments makes it possible to concatenate bending movements and thus overcome obstacles that a rigid robot would not be able to overcome.

In conjunction with this, a validation test was proposed whose purpose was to demonstrate PAUL’s ability to flex thanks to its deformable geometry. The aim was to point points in lateral planes. The results of this experiment are shown in Figure 19. The images, extracted from the video of Appendix A, show how the manipulator can adopt different shapes, is able to bend up to 40◦ and adapt, in case of obstacles, to a wide variety of geometries, which undoubtedly makes PAUL a fundamental ally in inspection and exploration operations in very cluttered environments.

This paper is available on arxiv under CC BY-NC-SA 4.0 DEED license.